The Green Fairy calls again

http://www.oxygenee.com/

La Fee Verte Absinthe House

http://www.feeverte.net/

Erowid - Absinthe

http://www.erowid.org/chemicals/absinthe/

Dancing With The Green Fairy

http://absinthe.msjekyll.com/index.html

http://en.wikipedia.org/wiki/Absinthe

Sebor Absinth

http://www.seborabsinth.com

The Jade Range of Belle Epoque Absinthes

http://www.absintheclassics.com/absinthe_jade.html

http://www.absintheclassics.com

Liqueurs de France

http://www.absintheonline.com/

Absinthe - Buy the Green Fairy online at ALANDIA

http://www.alandia.de

----------------------------

Absinthe Chemistry

From Anne Marie Helmenstine, Ph.D.,

Your Guide to Chemistry.

http://chemistry.about.com/od/chemistryhowtoguide/a/absinthe.htm

History, Chemistry, Recipes, and How to Drink Absinthe

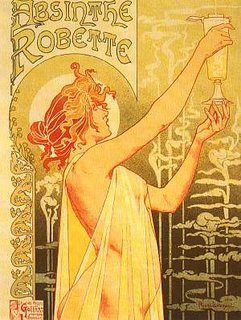

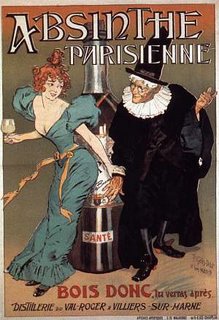

Absinthe is a wormwood and anise flavored liqueur that was highly popular in France circa 1880 – 1914. Although sometimes colorless, the slightly bitter spirit is traditionally bright green. It has also been known as 'le fee vert', or 'the green fairy'.

Dr. Pierre Ordinaire, a French doctor, is credited with creating absinthe in 1789. He mixed wormwood and other herbs with alcohol to make a 136 proof elixir, which he used to treat the sick. According to some reports, Dr. Ordinaire gave his recipe to Mademoiselle Grand-Pierre, who supposedly sold it to two sisters named Henroid. Other reports indicate the Henroid sisters were making absinthe before the Dr. Ordinaire arrived. In any case, the Henroid sisters offered samples of the elixir to sell in pharmacies. In 1797, they sold their recipe to a Frenchman named Major Dubied.

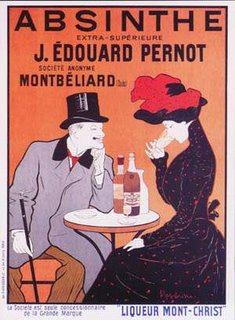

The Major, his son Marcellin, and son-in-law Henri-Louis Pernod built the first commercial absinthe distillery in Couvet. In 1805 Pernod opened a larger factory called "Maison Pernod Fils". At the height of production, this factory produced 30,000 liters of absinthe per day, which was distributed around the world. Pernod Fils' original recipe included six aromatic herbs: wormwood (Artemisia absinthium), Roman wormwood (Artemisia pontica), hyssop, lemon balm, fennel and anise. Herbs added into later recipes include angelica, dittany, juniper, nutmeg, and star anise.

Absinthe has appeared in works by Pablo Picasso and Vincent Van Gogh. It was popularized by famous artists and writers including Oscar Wilde, Toulouse-Lautrec, Gaugin, Cezanne, Charles Baudelaire, Edgar Allen Poe, and Ernest Hemingway. By the end of the 19th century, absinthe was the spirit of choice, particularly in France, where the cocktail hour became known as as 'L'Heure Verte', or 'the green hour'.

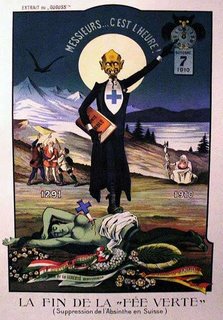

However, the drink became associated with an outcry over alcoholism, sometimes called 'Absinthism', and there were concerns over its potential effects on the nervous system. In August 1905, the farmer Jean Lanfray shot his family. European news headlines stated he was under the influence of absinthe (he had also consumed several bottles of wine and other alcohlic beverages that day). Public outcry ensued over the sensational headlines. Over the next few years absinthe was banned in many countries.

Most of the blame for the reputed deleterious effects of absinthe was directed at the wormwood used to flavor the drink. Wormwood, Angelica absinthium, contains the terpene thujone, which is used for medicinal purposes, but is toxic in high doses. Interestingly, thujone is present in the culinary herbs sage and tarragon and is used to flavor another (non-banned) alcoholic beverage, vermouth. More likely, the hallucinations and purported insanity resulted from the presence of toxic impurities or additives. For example, the green coloration the spirit derives from herbs was sometimes achieved through the addition of cupric acetate and other copper salts. Antimony trichloride was added to some preparations to enhance the louche effect (the opalescent milkiness seen when water is added to the liqueur).

At the time of this writing, authentic absinthe containing thujone is not sold in the United States. The thujone levels in commercially distilled absinthe must be 10 mg/l or less in order to comply with European Union (EU) limits. The thujone levels in commercially distilled absinthe in Germany must be 30 mg/l or less. Herbal kits for making absinthe are widely available, however, these kits tend not to rely on distillation, which is required to make traditional absinthe.

How to Make Absinthe

Absinthe is prepared by steeping herbs in a neutral spirit and then distilling the product of the mixture. Wine is the traditional alcohol, called the 'proof spirit' for this process, although vodka is used for some recipes. After the steam distillation, additional herbs are allowed to infuse the distilled spirit, which is then filtered before consumption. Therefore, the steps to preparing absinthe are:

1. Obtain a neutral spirit. A prepared neutral spirit, such as vodka, could be used, or wine may be distilled to obtain a more concentrated spirit.

2. Add macerated herbs to the proof spirit. Allow the aromatic oils from the herbs to infuse the spirit. The dry herbs are mixed with the wine spirits or vodka or another spirit that is at least 85% ethanol. The maceration is allowed to rest for several days in a cool location out of direct light, shaken occasionally.

3. At the end of this time, the mixture is filtered and added to water (half the volume of water as the amount of proof spirit, e.g., half a liter of water if a liter of alcohol was used).

4. Distill the maceration. The distillation process is essentially the same as that used to make moonshine. The heads and tails, or the liquid obtained at the very beginning and end of the distillation, are discarded. The remaining liquid is collected and reserved. For some absinthe recipes, this is the final product.

5. Traditional green absinthe is prepared by adding more herbs to the distilled product. This step is referred to as 'the finish'. These herbs add flavor and impart the green color to the spirit. After the flavor and color of the finish herbs has been imparted to the spirit, it is then filtered and ready for use.

Absinthe Recipes

Recipes for absinthe generally have two parts. There is the maceration, which is the list of herbs to be soaked in the proof spirit prior to distillation, and the list of finish herbs, which are herbs infused into the spirit after the distillation. After the finish has had time to work its way into the liqueur, it is filtered and ready for use or storage. Absinthe should be bottled in tightly sealed containers, as with corks or screw caps. Absinthe should be stored in a cool location (steady 13-18°C), away from direct sunlight. Bottles with a cork may be stored on their sides and rotated to keep the cork moist. Bottles with screw on caps should be stored upright to prevent leaking.

Spanish Absinthe

(Primary Maceration for Distillation - 1.5 liters)

* 4 grams - Common Wormwood

* 8 grams - Green Anise (Seeds)

* 6 grams - Fennel Seed

* 12 grams - Star Anise

* 2 grams - Angelica root

* 1 gram - Coriander

(Finish)

* 2 grams - Hyssop

* 3 grams - Melissa (Lemon Balm)

Suisse La Bleue (clear absinthe)

(Primary Maceration for Distillation - 1.5 liters)

* 4 grams - Common Wormwood

* 8 grams - Green Anise (Seeds)

* 6 gram - Fennel Seed

* 4 grams - Star Anise

* 3 grams - Peppermint Leaf

* 2 grams - Hyssop

* 2 grams - Angelica root

French Absinthe

(Primary Maceration for Distillation - 1.5 liters)

* 3 grams - Common Wormwood

* 4 grams - Green Anise (Seeds)

* 2 gram - Fennel Seed

* 2 grams - Star Anise

* 2 grams - Angelica root

* 1 gram - Coriander

(Finish)

* 2 grams - Hyssop

* 2 gram - Melissa

Winston's La Fee Verte

(Primary Maceration for Distillation - 1.5 liters)

* 4 grams - Common Wormwood

* 6 grams - Green Anise (Seeds)

* 4 gram - Fennel Seed

* 8 grams - Star Anise

* 2 gram - Hyssop

* 4 grams - Peppermint Leaf

* 2 grams - Angelica root

(Finish)

* 2 grams - Hyssop

* 2 grams - Melissa

* 4 grams - Peppermint Leaf

Absinthe Recipe Notes:

* The proof spirit is usually distilled from wine.

* Flowers and leaves of wormwood are preferred for their aromatic and fresh flavors.

* The stems of wormwood have a higher thujone content than the leaves and flowers and also impart more of a bitter note. Most recipes do not call for wormwood in the finish, because addition of the fresh herb at this point can add too much astringency. If wormwood in the finish is desired, it is recommended that a small quantity be used.

* Wormwood, peppermint leaf, and hyssop are usually the source of the green color associated with absinthe. The louche is due to a reaction with the anise in the spirit.

Distillation - Quality absinthe is slowly distilled from wine, also known as the "proof-spirit".

Wormwood - Whenever possible, use the flowers and leaves for their aromatic and fresh flavors. When available, use an organic grown wormwood. Organic grown wormwood will be free of pesticides. Organic wormwood is often grown and harvested with care. The quality of the wormwood will have a direct impact on the quality of the absinthe. Use wormwood that consist of the dried leaves and flowers, and free of stems and powder residue.

Note: The oils produced by the flowers and leaves are lower in thujone than the stems.

Color - Wormwood, Peppermint Leaf, and Hyssop can be used to produce the green color associated with absinthe. Our recipes are free of Wormwood in the finish. I think the use of wormwood in the finish adds back the astringencies that were removed in the steam distillation process. If you use Wormwood in the finish, we suggest using a "very" small amount.

---------------------------------------------------

What Is Distillation?

A. Distillation is a widely used method for separating mixtures based on differences in the conditions required to change the phase of components of the mixture. To separate a mixture of liquids, the liquid can be heated to force components, which have different boiling points, into the gas phase. The gas is then condensed back into liquid form and collected. Repeating the process on the collected liquid to improve the purity of the product is called double distillation. Although the term is most commonly applied to liquids, the reverse process can be used to separate gases by liquefying components using changes in temperature and/or pressure.

Distillation is used for many commercial processes, such as production of gasoline, distilled water, xylene, alcohol, paraffin, kerosene, and many other liquids.

Types of distillation include simple distillation (described here), fractional distillation (different volatile 'fractions' are collected as they are produced), and destructive distillation (usually, a material is heated so that it decomposes into compounds for collection).

http://chemistry.about.com/cs/5/f/bldistillation.htm

----------------------------------

How To Distill Ethanol or Grain Alcohol (moonshine)

Ethanol is also called ethyl alcohol or grain alcohol. It's made from a fermented mixture of corn, yeast, sugar, and water. The resulting alcohol is 100 to 200 proof (200 proof is pure alcohol).

In addition to use in the lab, ethanol is a popular fuel alternative and gasoline additive. Because it is flammable, ethanol can be prohibitively expensive to ship, so it may make sense to distill your own. Anyone can have a still, but be advised you may need to get a permit in order to make ethanol.

Difficulty: Easy

Time Required: 3 - 10 days, sometimes longer

Here's How:

1. If you are starting with whole corn, you first need to convert the cornstarch into sugar by 'sprouting' the corn. Place the corn in a container, cover it with warm water, and drape a cloth over the container to prevent contamination and conserve heat. Ideally, the container will have a slowly draining hole at the bottom. Add warm water from time to time as the liquid level falls. Maintain the setup ~3 days or until the corn has sprouts about 2 inches long.

2. Allow the sprouted corn to dry. Then grind it into meal. Alternatively, start with cornmeal. Other grains can be prepared in much the same way (e.g. rye mash).

3. Mash or mush is made by adding boiling water to the corn meal. The mash is kept warm to start the fermentation process. Yeast is added, if available (half pound yeast per 50 gallons of mash, for example), and sugar (variable recipe). With yeast, fermentation takes about 3 days. Without yeast, fermentation could require more than 10 days. The mash is ready to 'run' once it stops bubbling. The mash has been converted into carbonic acid and alcohol. It is called 'wash' or 'beer' or 'sour mash'.

4. The wash is placed into a cooker, which has a lid that is pasted shut, so that it has a seal which can be blown off should internal pressure become too great. At the top of the cooker, there is a copper pipe, or 'arm' that projects to one side and tapers down from a 4-5 inch diameter to the same diameter as the 'worm' (1 to 1-1/4 inch). The 'worm' could be made by taking a 20 ft length of copper tubing, filling it with sand and stopping the ends, and then coiling it around a fence post.

5. The sand prevents the tubing from kinking while being coiled. Once the worm is formed, the sand is flushed out of the tube. The worm is placed in a barrel and sealed to the end of the arm. The barrel is kept full of cold, running water, to condense the alcohol. Water runs in the top of the barrel and out an opening at the bottom. A fire is maintained under the cooker to vaporize the alcohol in the wash.

6. The ethanol vaporizes at 173°F, which is the target temperature for the mixture. The spirit will rise to the top of the cooker, enter the arm, and will be cooled to the condensation point in the worm. The resulting liquid is collected at the end of the worm, traditionally into glass jars. This fluid will be translucent, and about the color of dark beer.

7. The very first liquid contains volatile oil contaminants in addition to alcohol. After that, liquid is collected. The containers of liquid collected from over the wash are called 'singlings'. Liquid collected toward the end of this run is called 'low wine'. Low wine can be collected and returned to the still to be cooked again. The initial collections are higher proof than those collected as the distillation progresses.

8. The singlings tend to have impurities and require double-distillation, so once the low wine has been run to the point where a tablespoon or so thrown on a flame won't burn (too low proof), the heat is removed from the still and the cooker is cleaned out. The liquid remaining in the still, the 'backings' or 'slop', can be recovered and poured over new grain (and sugar, water, and possibly malt) in a mash barrel for future distillations. Discard mash after no more than eight uses.

9. The singlings are poured into the cooker and the still is returned to operation. The initial collections can approach pure alcohol (200 proof), with the end collections, using the flash test on the flame, at about 10 proof.

10. The desired proof depends on the application. The highest proof usually obtained from a still is 190 proof. For using alcohol as a fuel alternative, for example, addition purification with a sieve may be required to obtain 200 proof ethanol.

Tips:

1. If you live in the United States, a permit may be required in order to legally distill ethanol.

2. Stills traditionally were operated close to a water source, like a stream or river, because the cool water was used to condense the alcohol in the tubing (called the 'worm')

3. Stills needed to have removable tops, so that they wouldn't explode when pressure built up from heating the mash.

What You Need:

* 25 lb corn meal or 25 lb shelled whole corn

* 100 lb sugar (sucrose)

* 100 gallons water

* 6 oz yeast

http://chemistry.about.com/od/chemistryhowtoguide/ht/ethanol.htm

----------------------------------

ABSINTHE RECIPE

(From Dale Pendell's Pharmako/Poeia)

http://www.erowid.org/chemicals/absinthe/absinthe_recipe1.shtml

30.0 g wormwood

8.5 g hyssop

1.8 g calamis

6.0 g melissa

30.0 g anise seed

25.0 g fennel seed

10.0 g star anise

3.2 g coriander seed

Put the dry herbs in a large jar. Dampen slightly. Add 800 ml of 85-95 percent ethyl-alcohol (use alcohol suitable for drinking). Wine spirits make a better product than pure grain alcohol. Let it steep for several days - a week is better - shaking occasionally. Then add 600 ml of water and let the whole macerate for another day. Decant off the liquid squeezing as much from the mass of herb as possible. Wet the herbs with some vodka and squeeze again. Recipe should give a little over a liter and a half of green liquor. It must then be distilled. Inferior recipes skip this step, but what they produce is not worthy to be called absinthe.

In the distillation, change the receiver when the distillate turns yellow: those ar the faints. You can save the faints and add them to future distillations, but they will taint the flavor if added directly to the product. Just use the good stuff. The next step is to color and finish the liqueur by another round of maceration.

Color the distillate by again adding:

4.2 g mint

1.1 g melissa

3.0 g wormwood

1.0 g citron peel

4.2 g liquorice root

Let the herbs macerate for another three or four days. Decant, filter, bottle. You will probably want to carefully add some concentrated sugar syrup to the blend. The result will be a Swiss style absinthe of about 135 proof.Recipe makes one liter of absinthe.

ABSINTHE RECIPE

(From Dick's Encyclopedia of Practical Recipes, 1903)

http://www.erowid.org/chemicals/absinthe/absinthe_recipe2.shtml

IN a large cask:

1 1/2 lbs large absinthe (A. absinthium)

2 lbs small absinthe

2 1/2 lbs long fennel

2 1/2 lbs star anise

2 1/2 lbs green anise

6 oz coriander

1 lb hyssop

moisten with a little water, allow to swell.

add 12 gals. 95% alcohol, steep 3 days.

add 10 gals. water, steep another day.

Distill. Will produce 15 gals absinthe at 65-70%.

Change the receiver when the distillate turns reddish color.

That part has off flavors..

Color distilled product by steeping 10 or 15 days in

1/2 lb mint

1/4 lb melissa

1/2 lb small absinthe (A. pontica)

2 oz citron peel

1/2 lb bruised liquorice root.

Strain and filter.

1 Comments:

Thats so cute honey...I have such fond memories of meeting you and drinking absinthe. Is she calling again? Lets answer her. Love You Kiss Kiss from Kitty

Post a Comment

<< Home